Every now and again, a product is used in an application which isn’t fit for purpose and the consequence of doing so becomes evident very quickly. However, these situations can also be treated as lessons learnt and this brief article has been written to help understand the effects of high differential pressures across a flow control valve.

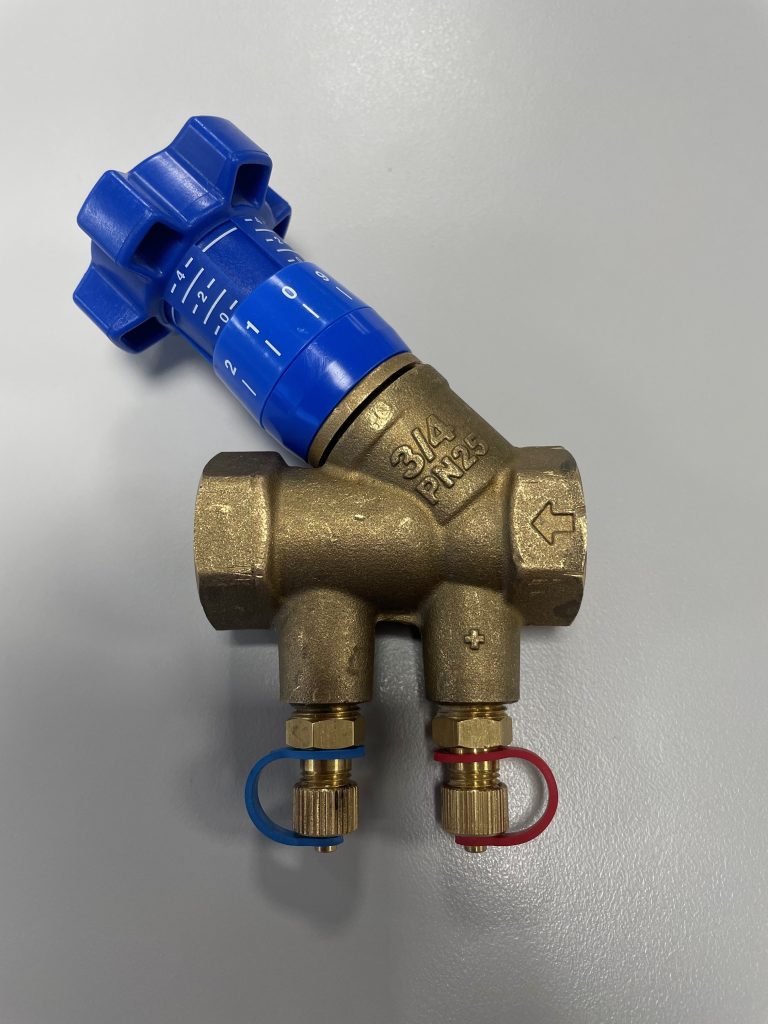

In this instance, unbeknownst to All Valve Industries, a Cimberio 746 series balancing valve was used to control the circulating flow of cold water through various circuits in a building, much like you would for a domestic hot water system, with the aim to reduce stagnant cold water and the risk of Legionella.

The issue was that rather than relying on a circulating pump with a relatively low head pressure for the circulation, the system used the mains water and booster pumps which were normally used to provide the peak flow demand to the building. This mains pressure water circulated through the system and back to an open tank for recirculation.

In order to provide the design flow for each circuit and balance the system, the Cimberio 746 series balancing valves were installed at the end of each circuit. Although the flow rates achieved were correct, the valves had to create a pressure loss of nearly 500kPa, whereby the maximum suggested pressure loss for these balancing valves is 50kPa.

The result of the valves creating this excessively high pressure loss was that cavitation occurred inside the valve and, within just 6 months, eroded the brass body to the point of failure. The tell tale sign of cavitation is the pitted rough surface structure and being located directly downstream of the ‘vena contracta’ which is the narrowest flow area that creates the pressure loss. The pictures show just how destructive the cavitation can be.

There are several alternative solutions to rectify the issue, for example, using a hydraulic style differential pressure sustaining valve at the end of the common return line which fed the tank, thereby reducing the pressure loss required across the balancing valves, or potentially redesign the system to not vent to the open tank and use a smaller circulating pump, or possibly use a control valve that featured an anti-cavitation trim (although unlikely available with Watermark approval).

This is just one example of cavitation in valves that All Valve Industries have seen over the years, but it serves as a reminder of the importance to carefully review manufacturer’s recommendations for the valve’s working conditions to ensure reliable performance for the life of the product.

For more information on cavitation, Flowserve provides a very good overview of this topic and you can read about it here;